Welcome to the Blog

How 3D Printing is Changing the Game

If you’ve ever seen a 3D printer in action, it’s easy to understand why additive manufacturing is capturing so much attention. What begins as a simple digital file transforms layer by layer into a fully realized object. This process, known as additive manufacturing (AM), is far more than a novelty. It’s a powerful technology that is redefining how products are designed, developed, and produced across a wide range of industries.

So, what exactly is additive manufacturing, and why is it such a big deal? Let’s break it down and talk about how 3D printing is changing the game in industries across the country.

What is Additive Manufacturing?

Additive manufacturing, often called 3D printing, is a way of making objects by building them one thin layer at a time. Instead of carving or cutting away from a big block of material, the machine adds just the right amount of material exactly where it’s needed.

The whole process starts with a digital design, usually made in CAD (computer-aided design) software. That design gets “sliced” into layers, kind of like turning a 3D object into hundreds or thousands of flat cross-sections. The printer then follows those instructions, stacking each layer until the full object takes shape.

One of the coolest things about this method is that it works with all kinds of materials, including plastics, metals, ceramics, and even composites. That’s why it’s used everywhere from classrooms and maker labs to aerospace and medical fields.

Why additive manufacturing matters?

1. Design Freedom

With Additive Manufacturing, you’re not limited to simple shapes. Want to design something with twists, hollows, or patterns that would be impossible to carve out? 3D printing makes that possible. It gives students and professionals the chance to really push the limits of their creativity.

2. Less Waste, More Efficiency

Traditional manufacturing can leave behind a lot of scrap material. Additive Manufacturing uses only what’s needed to build the object, which means less waste, lower costs, and a more sustainable way of making things.

3. Faster Prototypes

Got a new idea? Just print it! Instead of waiting weeks for a part to be made, you can have a working prototype in hours. That kind of speed is a game-changer for both learning and industry innovation.

4. Customization is easy

From custom medical implants to personalized school projects, additive manufacturing makes one-of-a-kind designs practical. It’s no longer about “one-size-fits-all”; it’s about making exactly what you need.

5. On-Demand Production

With Additive Manufacturing, you don’t need a giant warehouse full of spare parts and materials. Whatever you want to print can be printed whenever you want, wherever you want

Real-World Uses

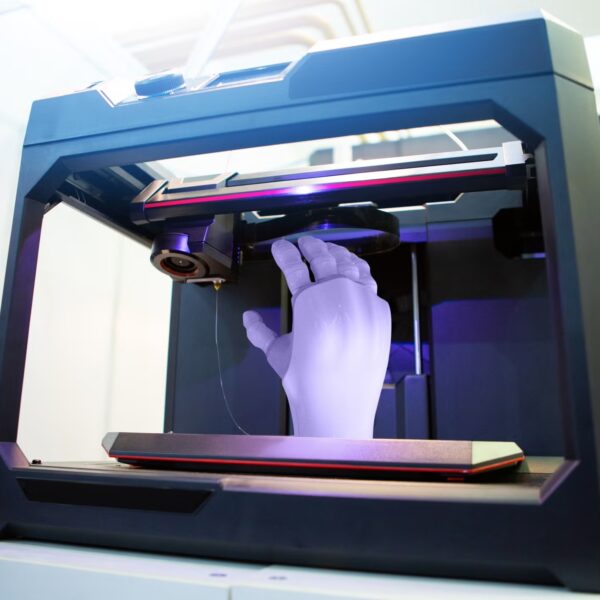

Healthcare:

3D printing is making a big difference in healthcare by helping doctors and patients in new ways. For example, prosthetic arms and legs can be printed to fit each person perfectly, and dentists can use 3D printing to make custom implants. Doctors even use printed models of organs to practice before surgery!

Aerospace:

3D printing is helping the aerospace industry build stronger, lighter, and more efficient parts for airplanes and rockets. Because every ounce of weight matters in flight, using 3D-printed components can save fuel and lower costs. The technology also makes it easier to create complex shapes that traditional manufacturing can’t handle, which improves performance and safety. From jet engine parts to spacecraft tools, additive manufacturing is helping engineers push the limits of what’s possible in air and space travel.

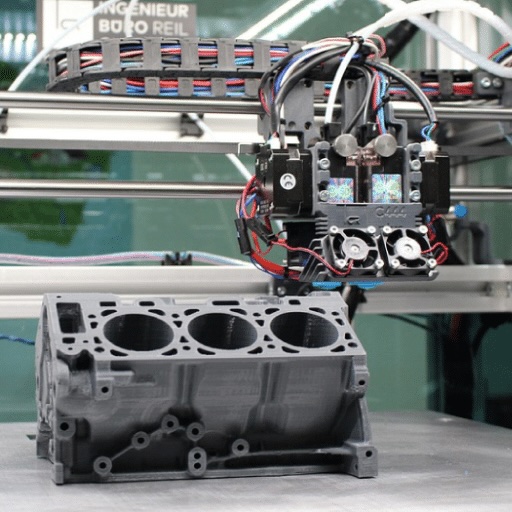

Automotive:

3D printing is changing the way cars are designed and built. Engineers can quickly print prototypes of new parts to test how they look and work before making them on a larger scale. This saves both time and money in the design process. Some car companies also use 3D printing to make custom or lightweight parts that improve performance. From race cars to everyday vehicles, additive manufacturing is helping the automotive industry move faster, become more creative, and even reduce waste.

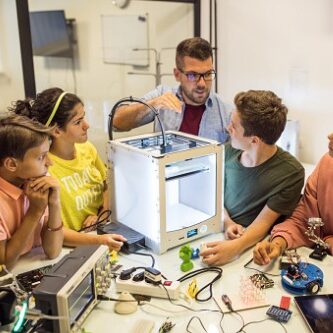

Education:

3D printing is a powerful tool for learning in classrooms and maker spaces. Students can turn their ideas into real objects, which helps them understand science, technology, engineering, and math (STEM) in a hands-on way. From building models of bridges to creating custom tools or prototypes, additive manufacturing makes lessons more interactive and fun. It also teaches problem-solving, creativity, and teamwork—skills that students will use in school and in future careers.

Why it matters

Additive manufacturing isn’t just about building parts; it’s about building skills. Students learn how to design, problem-solve, and think creatively while using technology that’s already changing industries. For instructors, it’s a way to make lessons more engaging, connect theory to practice, and prepare learners for the future of work.

The bottom line: Additive Manufacturing isn’t just the future of manufacturing, it’s here right now, and the more we understand it, the more opportunities we have to create, innovate, and make a real impact.