Share this article:

Belville, Illinois— On June 10th, 4 schools from across the country gathered at Southwestern Illinois College’s Advanced Manufacturing Academy facility to compete in a national advanced manufacturing competition. This three-day event provided a platform for the top teams to showcase their expertise in a variety of areas such as 5-axis CNC programming and machining, additive manufacturing, metrology, and precision assembly.

Project MFG’s Advanced Manufacturing Competition Series is a multi-round competition that began in October 2024. This season, there were 60 schools representing 31 states and 2 Canadian provinces registered to compete. After the initial qualifying round was completed, all of the team’s projects were submitted and judged, and out of the 60 teams that started, 16 were invited to move on to the Regional Rounds.

From those 16 teams, only 4 advanced to the National Championship held at Southwestern Illinois College’s brand new state-of-the-art Advanced Manufacturing facility. These teams represented all different parts of the country: Autry Technology Center (Oklahoma), Central Alabama Community College (Alabama), Everett Community College (Washington), Yuba College (California) Each team brought its own unique strengths, drawing from the expertise and regional industry partnerships that have shaped their respective programs.

“You’re it. You’re this next generation. You are world class and you are what is going to make US manufacturing world-class again. We couldn’t be more proud of the progress you made in such a short amount of time, but we should not stop here,” said Adele Ratcliff the former Director of the DoD Manufacturing Technology Program. “You’re on a journey to continue to promote the prestige of the trades, and this journey is going to allow us to reclaim that top position in the global environment.”

This season’s competition theme was space, and throughout the duration of the competition, students were challenged to manufacture key components that makeup and CubeSat.

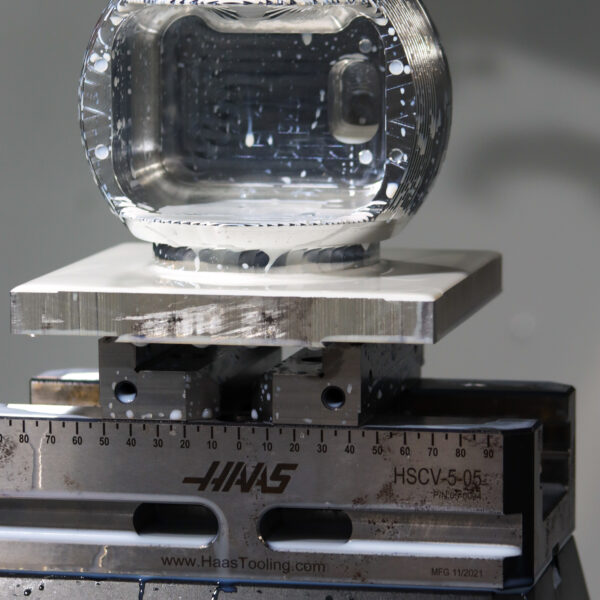

In the qualifying round, teams were tasked with manufacturing a gearbox. Out of the original 60 teams, the top 16 teams advanced to the Regional Rounds. In this round of the competition all 16 teams were required to manufacture and assemble a stabilizer, which is a component designed to theoretically support and hold an ISR sensor ball securely in place. The 4 teams that rose to the top and advanced on to the national championship faced the biggest challenge of them all.

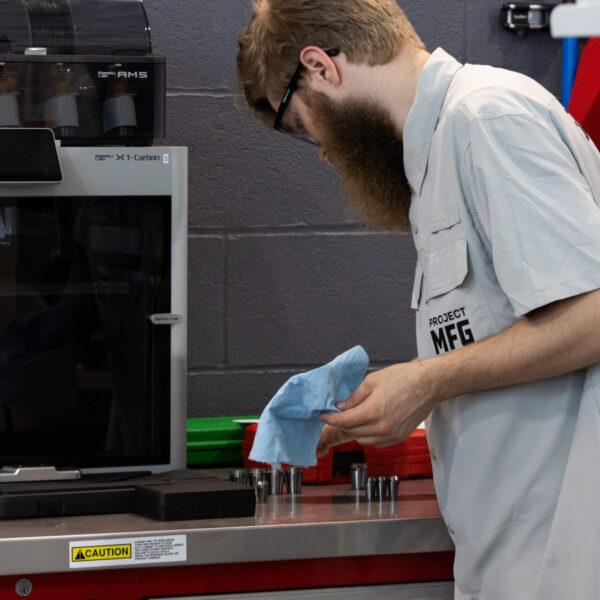

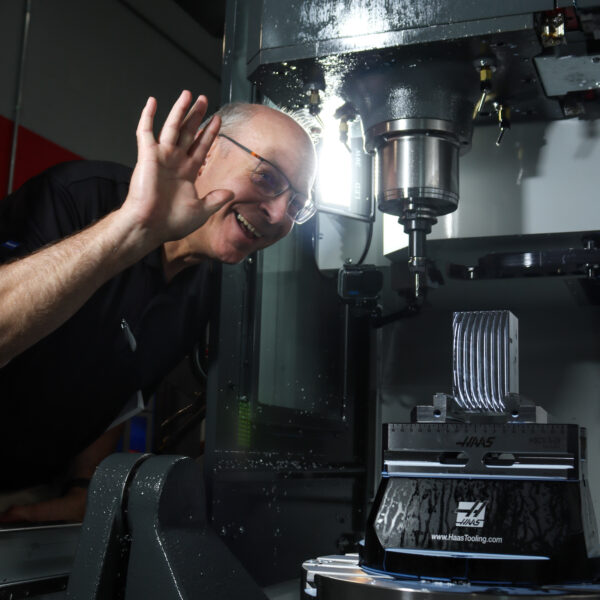

During the three-day event, teams were challenged to design and manufacturing a fully functional ISR Sensor Ball. This involved machining raw materials as well as incorporate additive manufacturing components to 3D print a thruster, and conduct precision measurements using advanced metrology tools with the help of our sponsor ZEISS.

The judging criteria emphasized not only technical accuracy and efficiency, but also teamwork, safety practices, cost of materials used amount of time the teams used to be on the clock working. The ultimate test? To see whether or not their completed project had the capabilities to hold a GoPro Camera, and when powered by a motor, rotate in a circle to bring the ISR sensor ball project to life and complete the CubeSat.

After the event, one team was crowned the 2025 Clash of Trades Advanced Manufacturing National Champion and walked away with the $100,000 grand prize. The team that came in 2nd place walked away with honorable mentions and a $50,000 cash prize, and lastly, the team that came in 3rd received a check for $25,000.

“This competition has opened doors we didn’t think possible,” said River Stormo, team captain for Everett Community College. “We’re grateful for the opportunity, and even more excited for what comes next.”

To find out who won, you will need to stay tuned for the release of our reality-style YouTube series that follows the students from the 3 Regional Rounds all the way to the National Championship. This behind-the-scenes series captures not only the technical intensity of the competition but also the personal journeys, challenges, and triumphs of the students as they push their limits and grow as future leaders in advanced manufacturing.

Viewers will get an inside look at the pressure-packed moments in the shop, the camaraderie that develops between competitors, and also get to hear some amazing stories from these competitors from all across the country. The series also features interviews with instructors, industry mentors, and judges, providing insight into the importance of workforce development and the high-demand careers available in modern manufacturing.

Meet the winners:

First-Place:

ANNOUNCEMENT SOON

STAY TUNED FOR THE RELEASE OF CLASH OF TRADES SEASON 5

Second-Place:

ANNOUNCEMENT SOON

STAY TUNED FOR THE RELEASE OF CLASH OF TRADES SEASON 5

Third-Place:

ANNOUNCEMENT SOON

STAY TUNED FOR THE RELEASE OF CLASH OF TRADES SEASON 5

FOURTH-Place:

ANNOUNCEMENT SOON

STAY TUNED FOR THE RELEASE OF CLASH OF TRADES SEASON 5

Event Photos

About Clash of Trades

At Project MFG, our mission is to empower the next generation of skilled trade professionals. Through high-intensity challenges, real-world scenarios, and expert mentorship, we’re equipping students with the tools they need to succeed in advanced manufacturing careers.

Now, we’re turning up the heat with Season 5 of our hit reality series, Clash of Trades—coming soon! Follow top student teams from across the country as they face off in a high-stakes journey to the National Championship in our latest season of the “Road to Nationals.”

Missed Season 4? Catch up now on our YouTube channel for behind-the-scenes footage, exclusive interviews, and all the drama from the competition floor.

While we gear up for the release of Season 5, don’t forget to subscribe to our YouTube channel so you never miss a moment of the action!

about project mfg

Project MFG is a catalyst that helps elevate the next generation of highly skilled trade professionals by changing mindsets, fostering community preparedness, and challenging how the critical skills needed to succeed in modern advanced manufacturing are taught. Through single and multiple technology competitions, participants gain hands-on experience with the latest technology and support from subject matter experts

For more information about Project MFG competitions and future events, please visit projectmfg.com or contact marketing@projectmfg.com.