Welcome to the Blog

From Aerospace to Furniture: 10 Industries Using CNC Machining Today

1. Aerospace

2. Automotive

CNC machining plays a big role in the automotive world—whether it’s prototyping new vehicle designs, producing custom parts, or creating large-scale components. From engine blocks and transmission housings to gears and aftermarket upgrades, CNC ensures precision at every step.

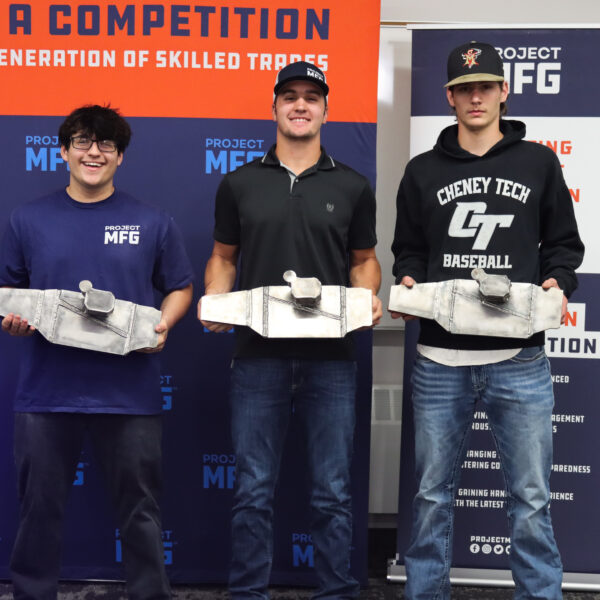

Want to see it in action? In Clash of Trades: Advanced Manufacturing Season 4, the spotlight was on automotive. Teams were challenged to manufacture real engine parts tough enough to go into a NASCAR race car!

3. Medical Devices

CNC machining is essential in the medical field, where precision can directly impact patient health and safety. It’s used to manufacture surgical instruments, orthopedic implants, prosthetics, dental devices and more! Precision in the manufacturing of these items is critical because each thing is designed to meet strict standards for accuracy, safety, and hygiene.

In Clash of Trades: Advanced Manufacturing Season 3, the spotlight was on medical devices. Teams took on the challenge of manufacturing parts for a hip replacement, putting their skills to the test in a real-world application.

4. Aviation

The aviation industry depends on CNC machining to create high-precision components like turbine blades, engine parts, and landing gear. By working with lightweight materials such as titanium and aluminum, CNC helps ensure safety, reliability, and better fuel efficiency in aircraft manufacturing.

In Clash of Trades: Advanced Manufacturing Season 2, the focus was on aviation. Teams were challenged to design and build an aviation-inspired test system featuring a customized wind turbine.

5. Robotics & Automation

Robots can only be as good as the parts they’re built from, and that’s where CNC machining comes in. This industry relies heavily on CNC machining to produce gears, joints, and frames that make robots move smoothly and reliably. The demand is only growing: the global precision machining market (which includes CNC) is projected to grow from about $107 billion in 2023 to $180 billion by 2030. That growth is being driven in large part by robotics and automation, showing just how important CNC skills are for the future of manufacturing.

6. Marine

From small recreational boats to massive ships, CNC machining plays a vital role in the marine industry. It’s used to create marine-grade parts that can withstand harsh environments, corrosion, and constant high stress. Common components include propellers, engine parts, and structural elements, but CNC also supports the production of precision fittings, brackets, and custom parts that keep vessels safe and reliable on the water. By combining durability with accuracy, CNC machining helps ensure performance from shipyard to open sea!

7. Defense & Military

Defense applications demand components that are rugged, reliable, and built with absolute precision. CNC machining supports this by producing everything from firearms and ammunition to parts for military vehicles, aircraft, and advanced communication systems. Because consistency and accuracy are non-negotiable in the field, CNC machining ensures mission-critical equipment performs exactly as expected, even under the toughest conditions. Beyond performance, CNC also allows for rapid prototyping and customization, giving defense teams the ability to adapt technology quickly to meet evolving needs!

8. Electronics

CNC machining is very important in the electronics industry, where even the smallest details matter. It’s used to make parts for phones, computers, gaming consoles, and more. These machines can create casings, tiny internal pieces, and parts that help stop devices from overheating. Since electronics are getting smaller and more advanced every year, CNC machining makes sure every piece is the right size and fits together perfectly so the device works the way it should.

9. Renewable Energy

CNC machining plays an important role in clean energy by helping build parts for wind turbines, solar panels, and hydroelectric systems. For example, it can make huge turbine hubs and shafts that have to be very strong and precise, as well as smaller parts like brackets and housings that need to fit perfectly for everything to work efficiently. CNC machines are also useful for testing new designs (prototyping) and for producing large numbers of parts once the design is ready. By making energy systems more reliable and efficient, CNC machining helps support the growth of renewable energy and a cleaner future.

10. Furniture

Beyond metals and plastics, CNC machining is transforming the world of woodworking! From crafting intricate, one-of-a-kind furniture pieces to streamlining large-scale productions, CNC machining brings unmatched precision and consistency to every cut. This technology empowers designers to push creative boundaries, producing complex patterns and detailed engravings that would be nearly impossible to achieve by hand. By combining speed, accuracy, and versatility, CNC machining is reshaping how wood is crafted, making both custom projects and high-volume production more efficient and innovative than ever before.

Final Thoughts

Overall, because of CNC machinings flexibility and reliability, this skill is important everywhere. From life-saving medical devices to advanced aerospace parts and everyday electronics, CNC machining turns ideas into real products with precision and speed. It can handle complex shapes and exact measurements, making it valuable for both prototypes and large production runs.

As technology evolves with AI, automation, and 3D printing, CNC machining will stay an essential part of manufacturing. Its ability to adapt means it will continue helping industries make high-quality, innovative products efficiently.