Welcome to the Blog

5 Benefits and Uses of CNC Machining

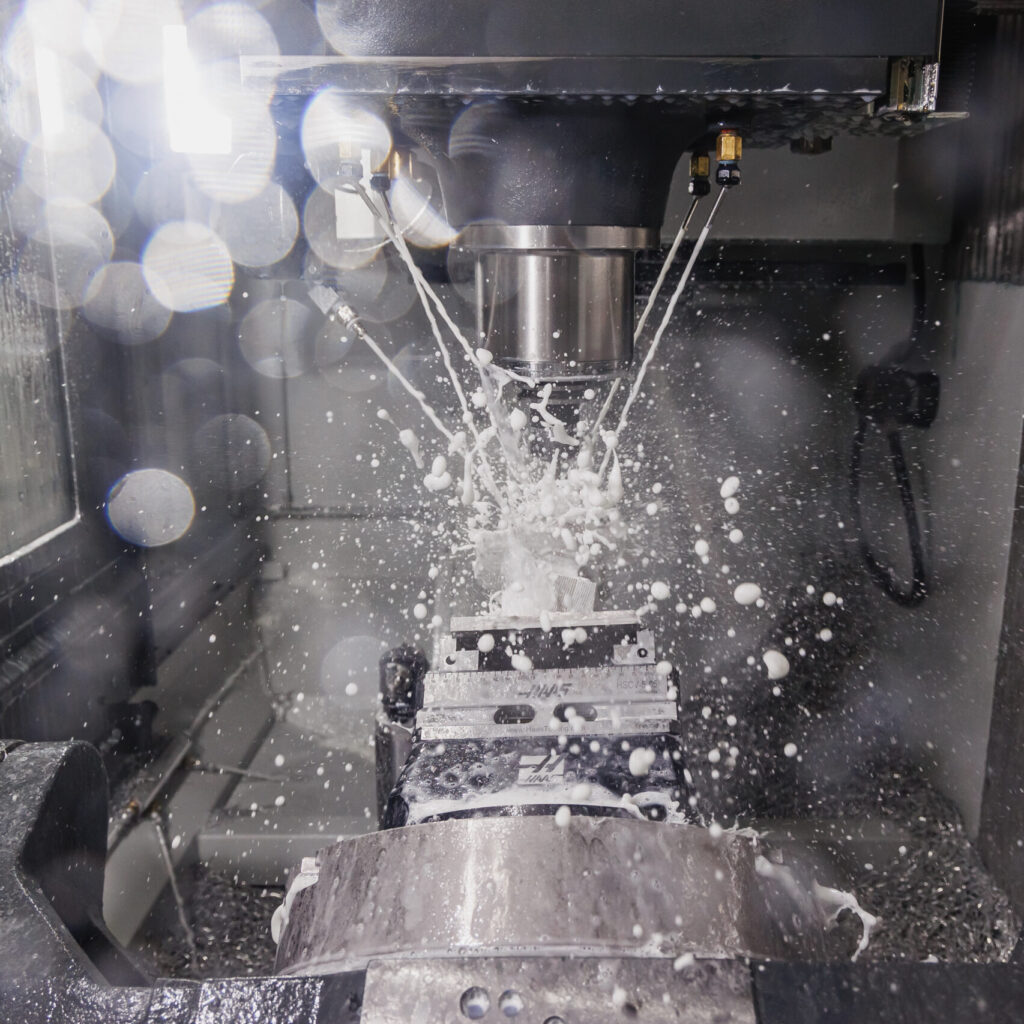

Manufacturing has evolved significantly over the years, particularly with advancements in technology. One of the key innovations is the use of CNC machines, which stands for computer numerical control. These machines have become a staple in many manufacturing settings because they can follow computer programs to carry out tasks like cutting, drilling, milling, and shaping materials. Thanks to CNC machines, factories can produce items more accurately, speed up production times, and create less waste, which ultimately helps lower costs and more! So, make to keep reading as in this blog we dive deeper and explore the top five benefits and uses of CNC machining.

1. Precision Design

CNC machining facilitates precision design through the use of computer-aided design (CAD) to generate intricate 3D models of components. These models are then converted into machine instructions (G-code) using computer-aided manufacturing (CAM) software, allowing the CNC machine to accurately cut and shape materials to meet the exact specifications of the design. From aerospace components to intricate jewelry designs, CNC machining is versatile and adaptable, allowing anything big or small, intricate or simple to be manufactured and meet the demands of various fields with ease.

2. Increased Efficency

One of the biggest advantages of CNC machines is that they can create parts much quicker than traditional methods while also ensuring that each part meets quality standards. CNC machines are programmed by trained machinists to operate continuously allowing them to work faster and reduce mistakes, leading to better efficiency and consistent results in manufacturing. Plus, CNC machines can run all day without needing breaks, which means production can keep going without stopping. This ability to work continuously and handle complicated tasks makes CNC machining a vital tool in today’s manufacturing industry.

3. Cost-Effectiveness

CNC technology, while having some initial setup costs, offers significant savings in the long run. One of its main advantages is that it operates automatically, which means you’ll need fewer workers to run it, lowering labor costs. Additionally, CNC machines are very precise, which helps reduce waste. This not only saves money but also helps use resources more wisely and reduces energy use during production. Overall, their efficiency in using materials and lowering costs makes CNC technology a smart choice for both small projects and large production runs.

4. Versatility

The adaptability of CNC machines allow them to be programmed for a wide variety of materials, including metals such as aluminum, steel, and titanium, as well as plastics like PVC, acrylic, and nylon, and natural materials including various types of wood and composites like fiberglass and carbon fiber. Because of their versatility, CNC machines are an essential resource across numerous industries; additionally, their computer-controlled nature allows for easy design modifications and the ability to switch between different cutting tools, further enhancing their versatility.

5. Safter work conditions

The fifth and final benefit of CNC machines that we want to highlight is how they create safer working conditions for machinists. Because these machines are mostly automated, there’s a much lower chance of accidents on the job compared to traditional machines that require more hands-on work. CNC machines are designed with various safety features, like stop buttons for emergencies, protective covers, and automatic tool changes, all of which help keep operators safe. These safety features not only protect the users but also contribute to a more secure and controlled environment in manufacturing.